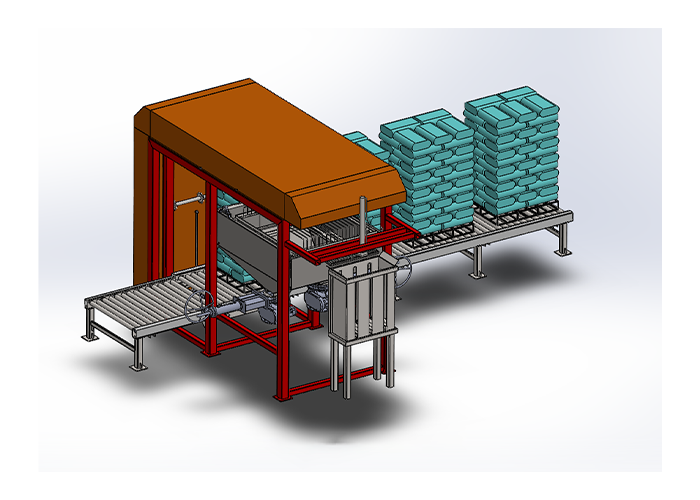

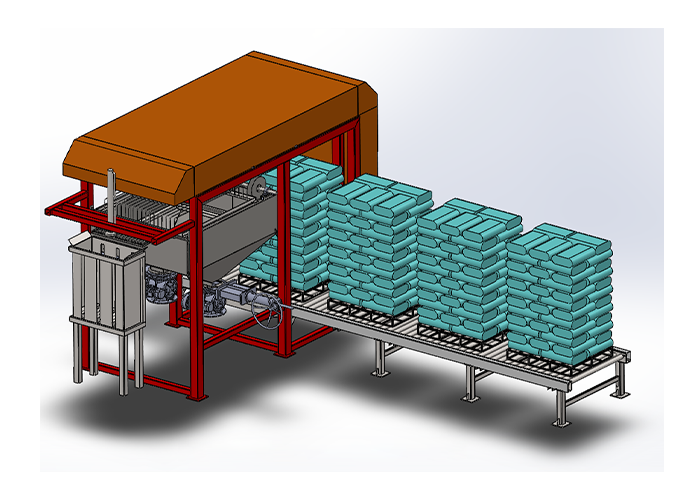

Automatic depelletising & bag Emptying machine

Our Automatic Depelletising & Bag Emptying Machines are engineered to handle the efficient and hygienic depelletising and emptying of bagged materials. These machines are perfect for industries requiring high-speed processing and minimal manual intervention.

Key Features

- High Efficiency : Handles high throughput, enhancing productivity.

- Dual Functionality : Combines depelletising and bag emptying in one machine.

- Dust Control : Enclosed system minimizes dust and contamination.

- Versatile Operation : Suitable for a variety of bagged materials including pellets and powders.

- Robust Construction : Built for continuous operation in demanding environments

Benefits

- Increased Productivity : Automates the process, reducing manual labor and increasing throughput.

- Enhanced Safety : Minimizes manual handling, reducing injury risks.

- Improved Hygiene : Enclosed design prevents contamination and maintains cleanliness.

- Cost Savings : Reduces labor costs and minimizes product loss.

- Customizable Options : Configurations available to meet specific needs.

Technical Details

| Bag Size Compatibility | Handles various bag sizes and materials. |

| Throughput Capacity | Up to 600 bags per hour. |

| Power Requirements | 220-480V, 3-phase, 50/60Hz. |

| Control System | PLC-based automation with HMI interface. |

| Construction Material | Stainless steel or mild steel options available. |

How It Works

The machine uses automated mechanisms to open and empty bags while simultaneously depelletising the contents. Bags are fed into the system where they are cut open, emptied, and the pellets are processed and discharged.

Application:

21

Years Of Experience

200

Project Completed

ISO

9001:2015 Certified

180

Customised solutions